TOTAL

HEAA CONTENT IN THIS SAMPLE IS 0.000% w/w

HYBRIDIZED

CORDYCEPS SPECIES:

Plot

5 shows a sample of Cordyceps sinensis mycelium powder, grown

in America on

a solid substrate of grain, utilizing unique culture parameters and a specially

hybridized, non-GMO strain of Cordyceps

sinensis. This strain is detailed in section two of this paper as

the most potent Cordyceps yet known, either from the wild or cultivated.

See plot 5:

PLOT

5 – HYBRID CORDYCEPS SINENSIS ALOHAENSIS

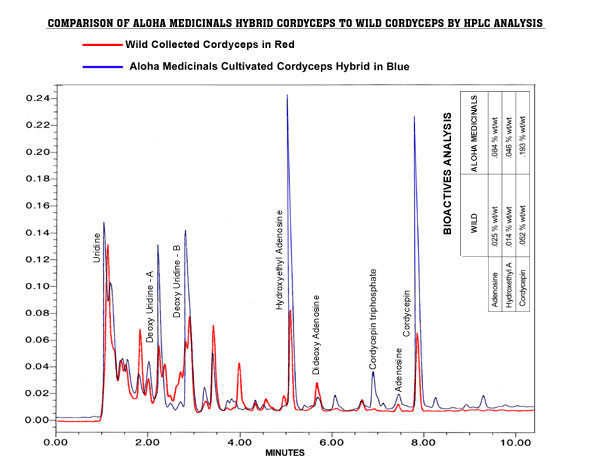

Plot

6 below is this same hybrid strain overlaid on a plot of wild Cordyceps

to show the comparison in quantity of active ingredients as well as the

qualitative similarities in the cultivated verses the wild Cordyceps.

The secondary metabolites produced are very nearly identical in these two

specimens of Cordyceps. See plot 6:

PLOT

6 – COMPARISON OF WILD TO HYBRID CORDYCEPS

PART

II – HYBRIDIZATION METHODS AND CULTURE MODIFICATION

CULTURE

METHODS AND SUBSTRATES:

In

looking at the variations in quality from different strains and producers

of Cordyceps, one must wonder what is it that causes this to be so.

After all, a tomato is a tomato, no matter where it is grown. Yet with Cordyceps,

even the same strain (CS-4) grown by different growers

turns out to be entirely different from a standpoint of active ingredients.

In looking

into this question, it is first important to realize that there are two

different methods used today in the cultivation of Cordyceps. There

is the method primarily used in China,

known as Liquid culture or Fermentation, in which the organism is introduced

into a tank of sterilized liquid medium, which has been formulated to provide

all of the necessary nutritional components for rapid growth of the mycelium.

After growth in the liquid medium, the mycelium is harvested by straining

it out of the liquid broth and drying, after which it can be used as-is

or further processed. Generally in this method the extra-cellular compounds,

which were exuded by the fungus during the growth cycle, are discarded with

the spent broth. This represents a major loss of bioactive compounds as

many of the active ingredients are extra-cellular in nature, and are found

only in small concentrations in the mycelium.

The second

cultivation method is the solid-substrate method followed by most growers

in Japan and

America. In this cultivation

system the mycelium is grown in plastic bags or glass jars full of sterilized

medium, which is almost always some type of cereal grain. This grain is

usually rice, wheat or rye although many different types of grain have

been used. After some period of growth, the mycelium is harvested along

with the residual grain. While this is an easily mastered and low capital

investment cultivation technique, the down side of this method is that

the grain content is usually greater than the mycelium content. In many

cases, the solid-substrate grown mycelium we tested was greater than 80%

residual grain. However, a bonus to this method is that the extra-cellular

compounds are harvested along with the substrate and mycelium.

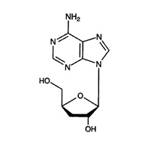

Cordycepin

is an example of one of the compounds that is primarily extra-cellular

in nature. Many tests have been done on cultured Cordyceps mycelium

for the presence of Cordycepin. What is found by these tests is that in

solid-substrate grown Cordyceps, there is usually Cordycepin present,

and in liquid-cultured Cordyceps, usually none. The presence or

absence of Cordycepin is dependent upon, among other factors, by which

method the mycelium was grown and harvested.

We can see

from this that the culture method itself has an effect on the quality

of the resultant Cordyceps product. Beyond the methodology itself,

the next most important factor in the production of particular secondary

metabolites (or target medicinal compounds) is the nature and composition

of the substrate itself. (Zhang, Zhao, Wu, Bai 1992) While it would seem

that a substrate that favors rapid and strong growth of the mycelium would

be an ideal substrate to use, this is not necessarily the case. Substrates

are chosen on availability and price, or on historical usage or preference

in handling. But rarely have they been chosen on the basis of the end

compounds produced. In fact, the only way to determine whether the substrate

being used is the best choice or not, is to compare the resultant product

after growth on that particular substrate with some standard. If the end

goal of production is Cordycepin or Didioxyadenosine (or some other specific

compound) - as it is with some of the pharmaceutical companies - then

the analysis is fairly straightforward. Just look for the amount of Cordycepin

or Didioxyadenosine present and work around that. But life in the health

supplement industry is rarely so simple. First we have to assume that

we know what it is that we are looking for. Since natural products such

as Cordyceps are chemically very complex, the truth is that we

do not really know all of the components that are bioactively important.

With this

realization in mind, we set out on a mission. To produce

the best Cordyceps possible. What is the best? Since we

did not know the answer to that question, we decided to try to copy the

natural, wild collected Cordyceps as closely as possible. We attempted

this by altering the substrate composition and analyzing the resultant

mycelial product for known bioactive compounds. Then

altering the substrate again…and again…and again. We did this through

several hundred different substrates and through many thousands of kilograms

of resultant product. What we found was that there was not any single

method, strain or substrate we could use that would yield the results

desired.

SUBSTRATE:

The

substrate of choice for most Chinese growers is a liquid media based upon

silkworm residue, with added carbohydrates and minerals. This seems a logical

choice, since this mushroom is found in nature growing on insects. Dried

silkworm bodies are the by-product of an existing industry and have little

other use. Therefore they are readily available and cheap. This silkworm-based

substrate seems to yield a relatively high quality product. The only problem

with silkworm- residue based substrate is that in the United

States,

the FDA requirements are for mycelial products to be produced on a normally

consumed human food source. Silkworms do not fit into that category. They

are also not available as a raw material source to most of the worlds Cordyceps

cultivators. The

most usual substrate for Japanese and American growers is rice. It was determined

in our trials that rice is not a suitable substrate for Cordyceps

production if the target medicinal compounds are considered. Rice does not

allow the full range of secondary metabolites to be expressed by the fungus,

and rice grown Cordyceps has tested inferior in all of our analyses

of active ingredient. There is rarely any appreciable amount of Adenosine

or Cordycepin present in rice-grown Cordyceps. Furthermore, there

are growth-stunting metabolites which build up in the substrate when Cordyceps

is grown on rice, limiting the growth stage to only about 22-24 days, and

allowing no more than about 40% of the rice to be converted into mycelial

mass. This figure of 40% represents the high end of conversion, and is usually

around 25-30%. This means that when Cordyceps is grown on rice then

dried and powdered, the resultant product is actually about 60-75% rice

flour.

Rye grain

is another substrate often used for solid culture, and it yields a higher

quality product than rice, as long as a source of vegetable oil as an

amendment is added to the growth medium at the time of substrate makeup.

The oil provides necessary nutrients, which the organism utilizes for

bioactive compound production. Rye has other disadvantages though. The

compounds in rye, which give it that characteristic rye smell and taste,

are not broken down by the Cordyceps and they concentrate in the

final product. This rye taste and smell overcomes the characteristic Cordyceps

taste and smell, and even though the resultant product is of better quality

than the rice grown mycelium, there are certain perceptual problems that

needs to be overcome by the buyer to make this an economical alternative.

Rice-grown Cordyceps may seem like a better product to the average

buyer because the rice does not mask the characteristic Cordyceps

smell and taste. Most buyers in the health supplements industry tend to

purchase bulk products on perception and faith rather than requiring an

independent analysis. Rye also has growth-limiting factors, which causes

the Cordyceps growth to stunt at about 28-30 days, although this

can be overcome to a slight degree with the addition of about 1% ground

oyster shell buffer to the medium at time of make-up. We tried many other

sources of calcium, but they did not seem to work as well as the oyster

shell calcium.

Millet is

a very good choice of substrate when it is available. It has no strong

taste or smell of it’s own, it does not stunt the growth to any significant degree

and it allows for the full expression of the secondary metabolites by

the organism. It has another problem though, which is the high ratio of

chitinous outer husk layer to starch. This outer husk is not broken down

and represents a large portion of the final product weight, about 15%.

The chitinous husk cannot be removed from the grain ahead of time, since

doing so allows the grain to become too sticky during sterilization and

a high degree of anaerobic contamination follows. The husk can be removed

from the final product through mechanical means such as a time-of-flight

separation, or the product can be used for hot water extractions or other

processing. Cordyceps does not grow as fast on millet as it does

on other grains, but the end product quality is higher.

White milo

grain, also known as white kaffir corn or white sorghum is an excellent

choice of substrate. The red variety of milo does not work nearly as well

as the white variety as a substrate. White milo has all of the best characteristics;

it is cheap, it has a high starch/husk ratio, it does not stunt the growth,

it allows the full expression of bioactive compounds and has no strong

odor or taste of its own to compete with the taste and smell of the resultant

Cordyceps product. White milo when used alone however lacks some

essential ingredients required for optimum growth by the Cordyceps.

The addition of some portion of millet to the white milo speeds up the

growth by a factor of 6 times. The millet to milo ratio is optimum at

1 part millet to 4 parts white milo.

Many farmers

grow both white milo and the red milo in the same fields, or store them

in the same silos, or otherwise do not keep the white and red separated.

This is to be avoided when used as a Cordyceps substrate, since

a small proportion of the red mixed in with the white can drastically

reduce the growth rate and overall quality of the final product.

So from

our substrate testing it was determined that the ideal medium for solid

substrate growth of Cordyceps is as follows: 1 part white proso

millet (husk on) to 4 parts of white milo (husk on), with the addition

of 0.8% w/w of ground oyster shell and 1% w/w vegetable oil (peanut oil

or soybean oil). Add water to equal 50% total moisture in the sterilized

substrate. Precooking the grain mixture for 4-6 hours prior to sterilization

tends to trigger a much faster growth response from the Cordyceps.

On this medium, Cordyceps can be grown for long periods of time,

allowing nearly complete conversion of the substrate to mycelium and the

full expression of secondary metabolites from the Cordyceps. The

resultant Cordyceps when grown on this substrate is about 3-4%

residual grain, or about 96-98% pure mycelium. The real benefit to this

method of growing is the capture of the entire compliment of extra-cellular

metabolites produced throughout the entire growth process. With the addition

of certain growth triggering compounds to this mixture, Cordyceps sinensis

is easily induced to fruit in culture without any insect material being

present. However the formation of the fruitbody on this medium does not

result in any significant change to the analytical chemistry profile.

CULTURE

PARAMETER MODIFICATION: LOW TEMPERATURE HYPOXIA

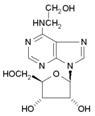

Using

the above-described substrate, the complete chemical profile of the cultivated

Cordyceps still will not approach that of the wild collected Cordyceps

unless it is grown under very specific conditions. Cordyceps sinensis

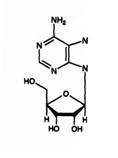

produces a relatively large amount of free Adenosine when grown at normal

atmospheric oxygen levels and room temperatures. It will also produce a

large quantity of Uridine and Guanosine. But there is very little if any

Cordycepin produced, and virtually no Hydroxyethyl Adenosine. For the organism

to produce these compounds, it needs to be growth-stressed through the absence

of oxygen, a drop in temperature and the total absence of light. Just growing

it under cold and anaerobic conditions from the start will not do the trick,

since when Cordyceps is grown under those conditions it forms a yeast-like

anamorph that has a very different chemical profile. It must first be grown

hot and fast, then tricked into converting its ‘summertime’ metabolites

into the target medicinal compounds we are looking for. To get these target

compounds, we found that we needed to follow a strict growth protocol: After

inoculation on to the millet/milo substrate, the Cordyceps is grown

at 20-22 degrees C, in diffuse light and at sea level atmospheric oxygen

for 28-30 days. It is then moved into a specially controlled environmental

chamber, where the oxygen is dropped to 50% atmospheric. The remainder of

the growth atmosphere is made up of Nitrogen, Carbon monoxide and Carbon

dioxide. The temperature is dropped to 3 degrees C, and all light is excluded.

It is held under these conditions for about 15-20 weeks. This results in

much of the Adenosine being converted to Cordycepin, Dideoxy-adenosine and

Hydroxyethyl-adenosine. Many other unique nucleosides are also produced,

with a final chemical profile identically matching that of the wild Cordyceps

as can be clearly seen in Plot 6.

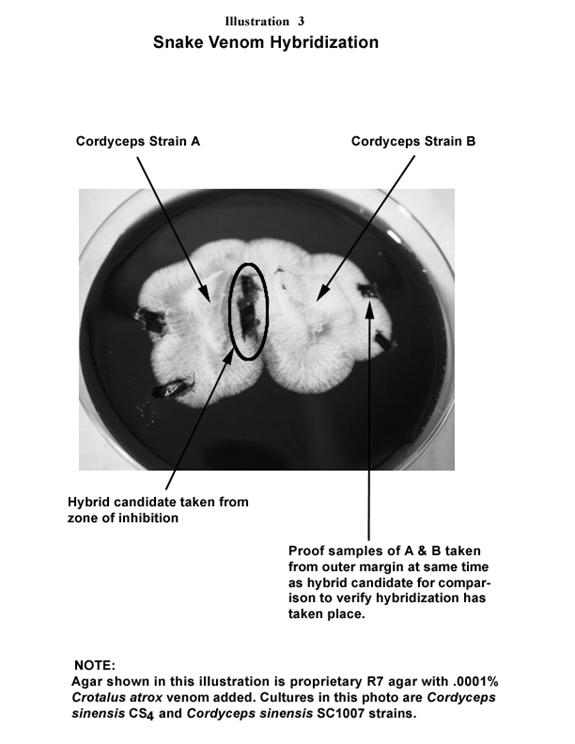

HYBRIDIZATION:

Once

we had developed the substrate and growth parameters to optimize the target

compounds, we started looking into the chemical profile differences from

different strains of Cordyceps sinensis. Since there were so many

strains of Cordyceps, and each strain has its own unique chemical

profile, we tested all of the strains we were able to obtain. None of the

known strains was shown to produce nearly the quantities of active ingredients

found in the wild Cordyceps. So we started experimenting with ways

to quantitatively increase the target compound production through the hybridization

of Cordyceps strains; to cross breed them in order to gain greater

production of target compounds. This was quite a challenge. Since spore

collection and separation is very time consuming and results in entirely

too much unknown variations, we felt this method would take too much time

before we had reliable results. Rather we took a novel approach. We experimented

with various ways to get different strains of the fungi to perform their

own nuclear fusion. There are several chemicals known to trigger this exchange

of genetic material between unlike cells. Nicotinic acid for instance, can

be used to create hybridized mycelium. This compound is difficult to use

and yields unreliable results. After trying several different compounds

to trigger this fusion, what we settled on was snake venom. See Illustration

1